Новое поступление

2 шт. Прямой соединитель всасывания внутреннего шлифования Женский 19/26 головной трубы.

10pcs 20x200mm Flat Bottom Glass Test Tube with Cork Lab Thickened Reagent Reaction Pipes |

1000ml Buchner Funnel Apparatus |

Лабораторный магнитный нагреватель SH-2A с алюминиевой панелью размером 12х12 см, скоростью вращения 100 ~ 2000 об/мин, объемом 2 л, типом нагрева и без функции перемешивания.

Сушильная печь Lab Small 18L с электрическим нагревом и постоянной температурой, настольный тип WHL Box 300°C PID LCD Display Microcomputer.

10 Counts 25x200mm Lab Glass Test Tube OD 25mm Length 200mm 80ml |

50 шт/лот Одноразовый шприц с иглой Пластиковый инжектор Кормовая пипетка Дозатор (1/2/5/10/20 мл) вкл.

Характеристики

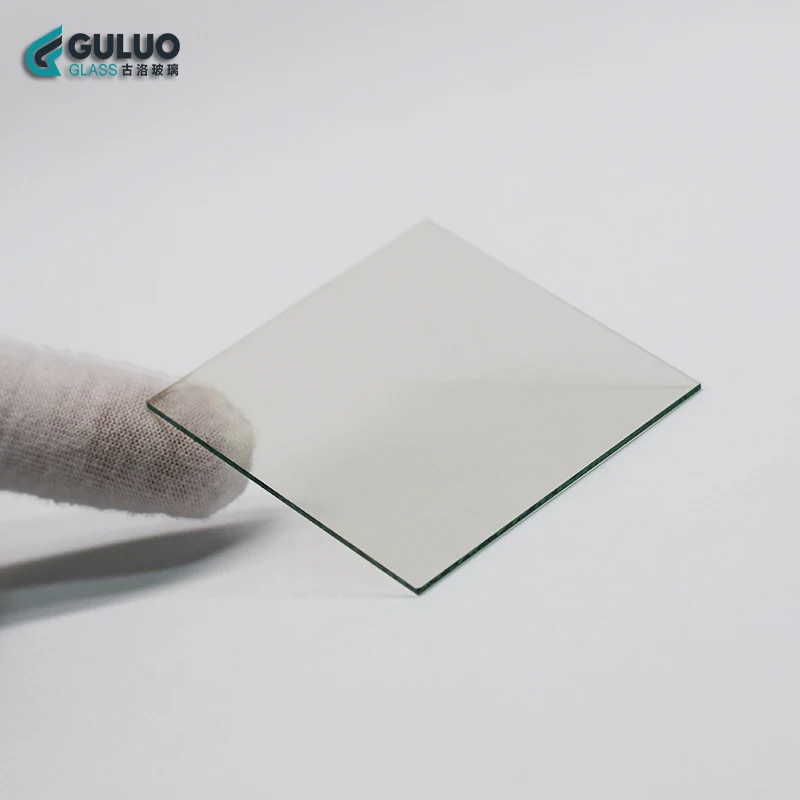

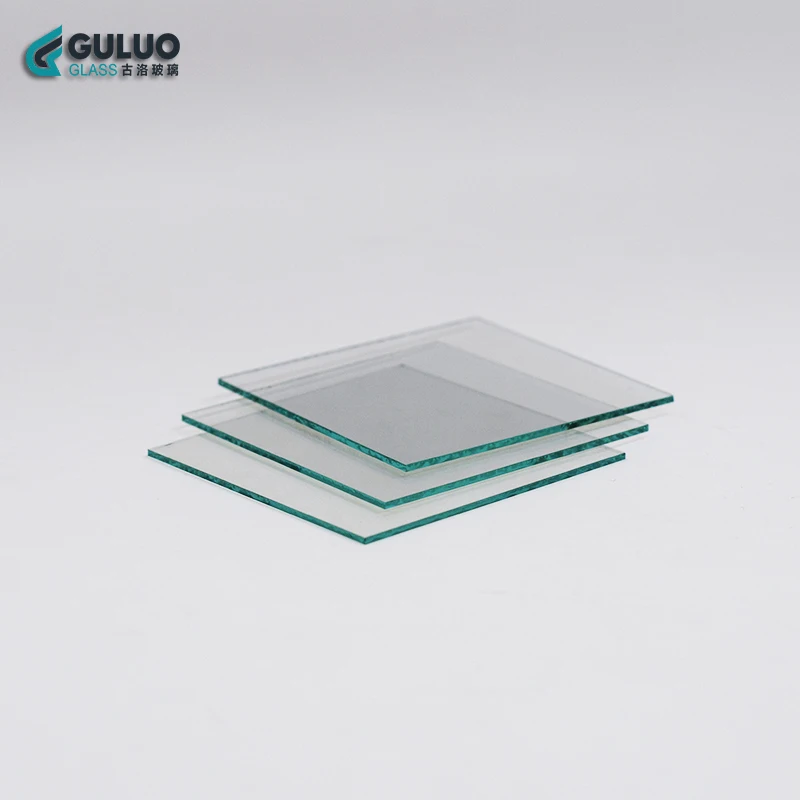

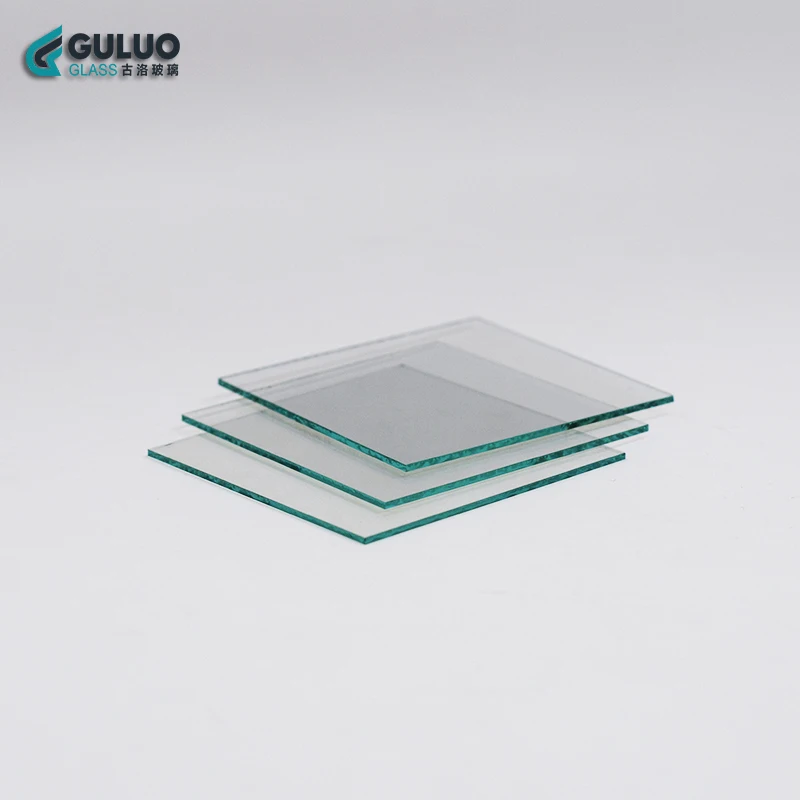

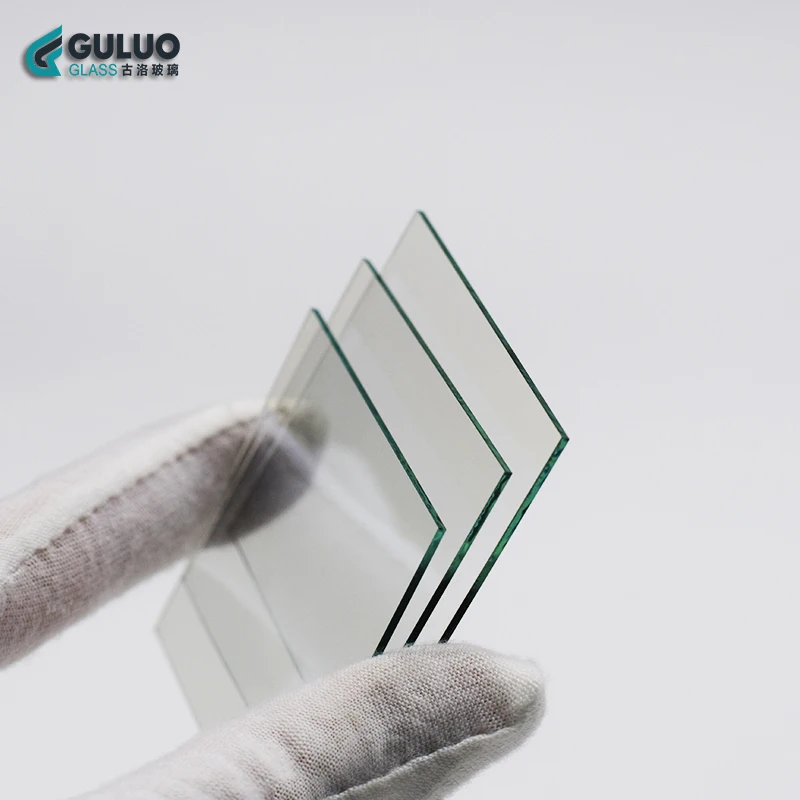

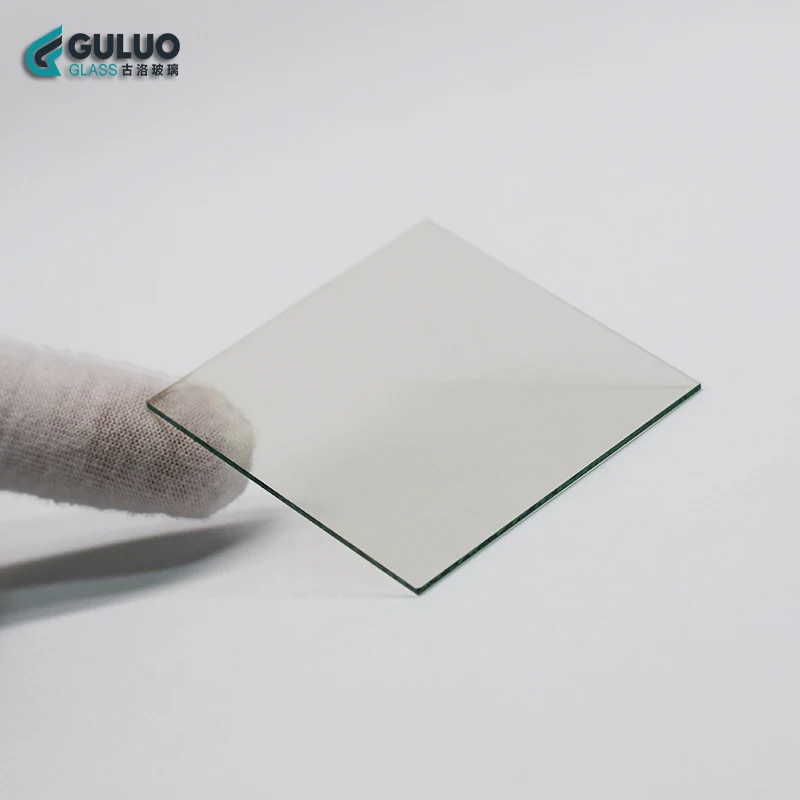

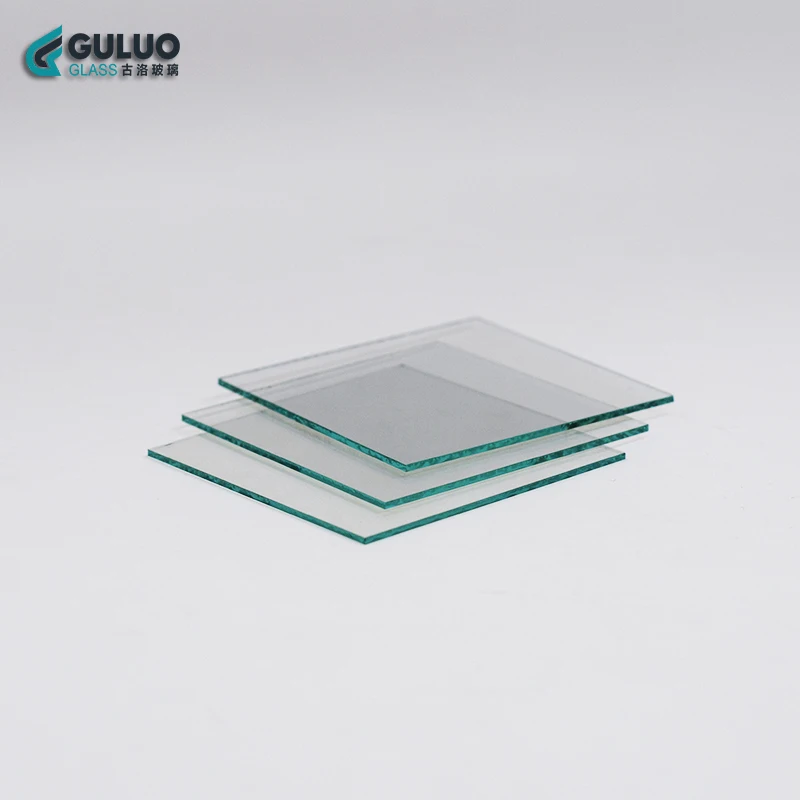

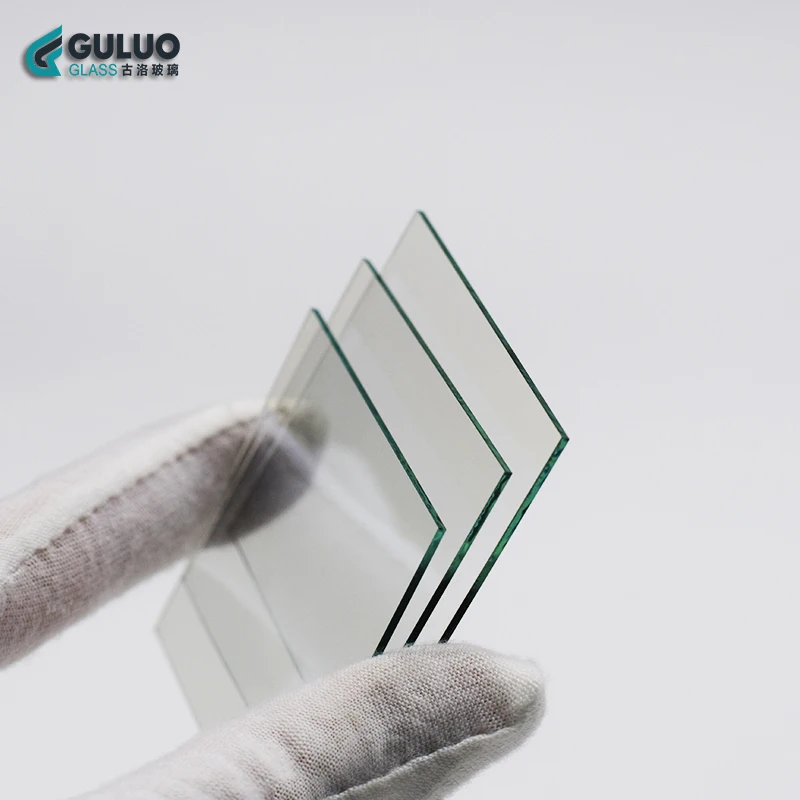

50x50x1.1mm 10 Ohm/Sq 10pcs Lab Transparent Conductive Glass Indium Tin Oxide ITO Coated | Petri Dish

История изменения цены

*Текущая стоимость 1195.1 уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Aug-18-2025 | 1518.10 руб. | 1548.9 руб. | 1533 руб. |

| Jul-18-2025 | 1231.10 руб. | 1256.15 руб. | 1243.5 руб. |

| Jun-18-2025 | 1494.55 руб. | 1524.81 руб. | 1509 руб. |

| May-18-2025 | 1482.83 руб. | 1512.14 руб. | 1497 руб. |

| Apr-18-2025 | 1183.10 руб. | 1207.63 руб. | 1195 руб. |

| Mar-18-2025 | 1458.67 руб. | 1487.86 руб. | 1472.5 руб. |

| Feb-18-2025 | 1446.96 руб. | 1475.23 руб. | 1460.5 руб. |

| Jan-18-2025 | 1434.98 руб. | 1463.59 руб. | 1448.5 руб. |

Описание товара

Brand NameGULUOModel NumberCustom processingOriginMainland ChinaClassificationPetri DishMeasurement unitpiece/piecesEach pack1050x50x1.1mm<10 ohm/sq1 195,10 ₽1 195,10 ₽loader

Description

Note: If you need to customize the shape, size, resistance, etching and scribing, please contact customer service! Or WeChat and SKYPE+8619937991926

Product name: ITO conductive glass Size: custom size Film thickness]: 30nm-380nm Transmittance: 78%-90% Product Type: Laboratory Supplies Production process: cutting, etching, straight edge, round edge, point corner, line drawing, grooving, hole opening, etc.

ITO conductive glass

ITO conductive glass is made of soda-lime substrate or Penggui substrate glass and coated with a layer of indium tin oxide (commonly known as ITO) film by magnetron sputtering. As a metal compound that does not have good transparent and conductive properties, it has the characteristics of forbidden bandwidth, high light transmittance in the visible spectral region and low resistivity. It is widely used in flat panel display devices, solar cells, special functional window coatings and other optoelectronic devices field.

ITO thickness: 0.4mm, 0.5mm, 0.7mm, 0.8mm, 1.0mm, 1.1mm, 1.5mm, 2.0mm, 3.0mm, other thicknesses can be customized

ITO resistance: 3-4 ohms, 4-6 ohms, 5-7 ohms/7-10 ohms, 10-15 ohms, 15-20 ohms, 20-30 ohms, 30-40 ohms, 40-60 ohms, 70 -120 ohms, other resistance values can be customized

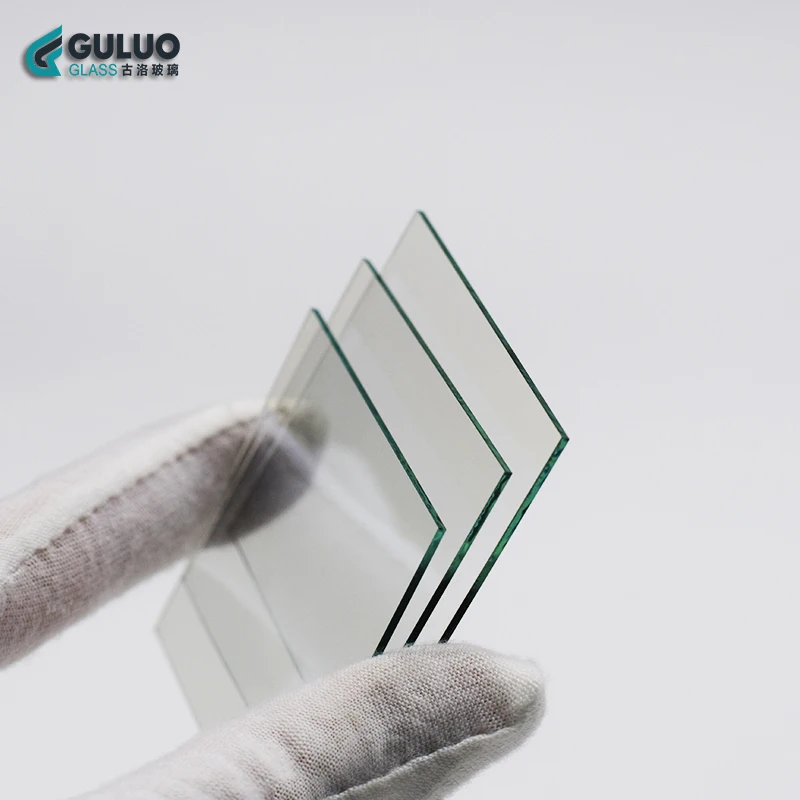

ITO glass characteristics

Alkali resistance: Alkali resistance means that after immersing in a 10% sodium chloride solution at 60°C for 5 minutes, the change in the square resistance of the ITO layer does not exceed 10%.

Acid resistance: Acid resistance means that after immersing in a 25°C, 6% hydrochloric acid solution for 5 minutes, the change in the square resistance of the ITO layer does not exceed 10%

Solvent resistant: After 5 minutes in a cleaning solution of 25°C, acetone, absolute ethanol or 100 parts of deionized water plus 3 parts of EC101, the change in the square resistance of the ITO layer does not exceed 10%

Adhesion: When the tape is attached to the surface of the film layer and quickly peeled off, the film layer is not damaged; the change of the square resistance of the ITO layer does not exceed 10% Stability: After heating for 30 minutes in the air at 300°C, the square resistance of the ITO conductive film should not exceed 300% of the original square resistance.

Conductive glass cleaning

During the production, packaging and transportation of ITO/FTO conductive glass, the surface of the glass may be contaminated by impurities such as dust, dust and grease. It is necessary to clean ITO and FTO conductive glass before using it. There are many cleaning methods, the most commonly used is ultrasonic cleaning with organic solvents. Grease stained on the glass surface is insoluble in water, but it is soluble in organic solvents such as toluene, acetone, and ethanol. Among them, toluene has the strongest decontamination ability, so first clean with toluene, but toluene cannot remain on the surface of the standard glass. Because toluene is soluble in acetone, it can be cleaned with acetone, which not only cleans out the residual grease, but also dissolves toluene. Similarly, acetone cannot remain on the surface of the glass. As acetone is soluble in ethanol, it can be cleaned with ethanol. Ethanol and water are mutually soluble in any ratio, and then use a large amount of deionized water to dissolve the ethanol, and finally put in anhydrous alcohol to store, and then take it out for use, so that you can wash multiple tablets at once. So generally: Toluene (10-20min) → Acetone (10-15min) → Ethanol (10-20min) → Deionized water (20-30min) in order for ultrasonic cleaning → anhydrous alcohol storage (take it out for long-term storage)

Смотрите так же другие товары: